LMFP: Powering the Next-Gen Batteries

You may have heard the saying: “𝐖𝐡𝐞𝐧 𝐲𝐨𝐮 𝐛𝐮𝐲 𝐚𝐧 𝐞𝐥𝐞𝐜𝐭𝐫𝐢𝐜 𝐯𝐞𝐡𝐢𝐜𝐥𝐞, 𝐲𝐨𝐮’𝐫𝐞 𝐫𝐞𝐚𝐥𝐥𝐲 𝐛𝐮𝐲𝐢𝐧𝐠 𝐭𝐡𝐞 𝐛𝐚𝐭𝐭𝐞𝐫𝐲.”

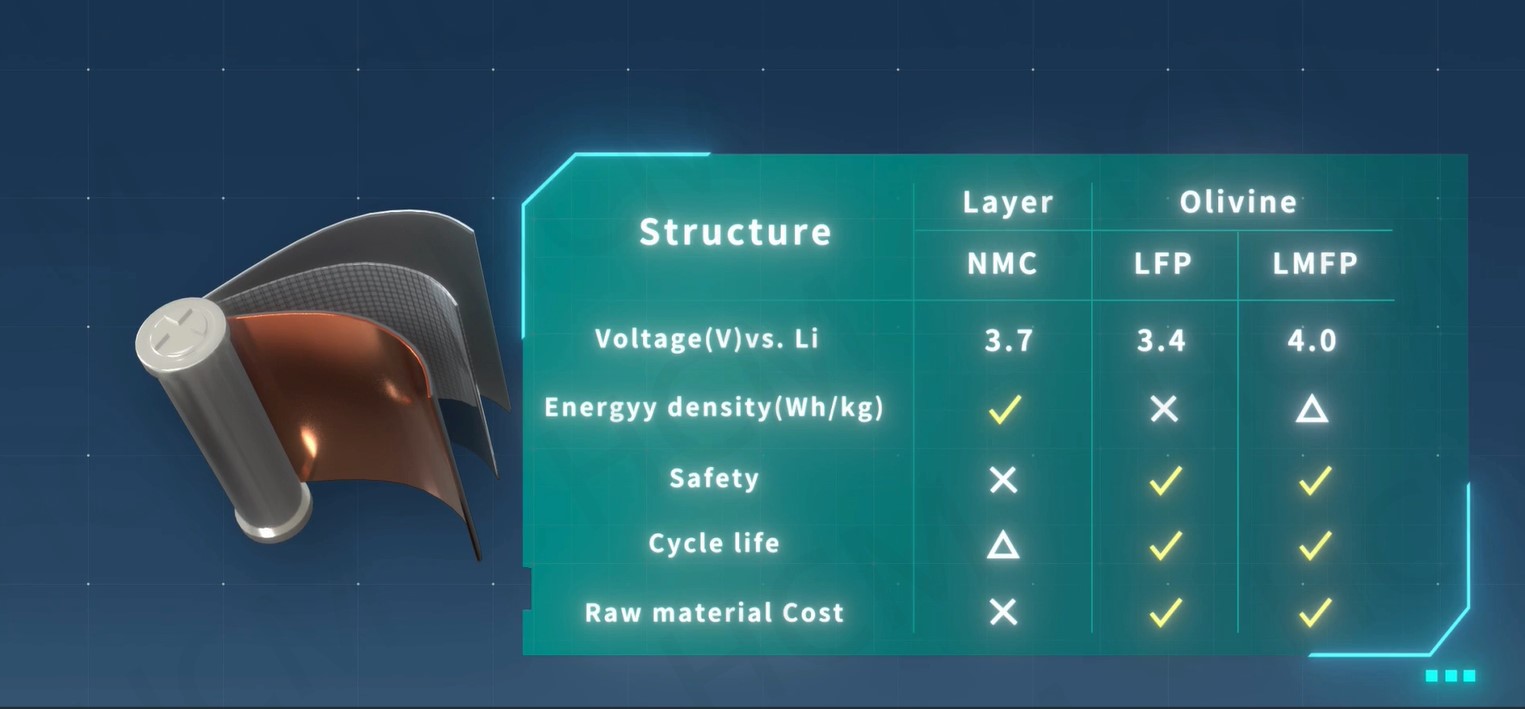

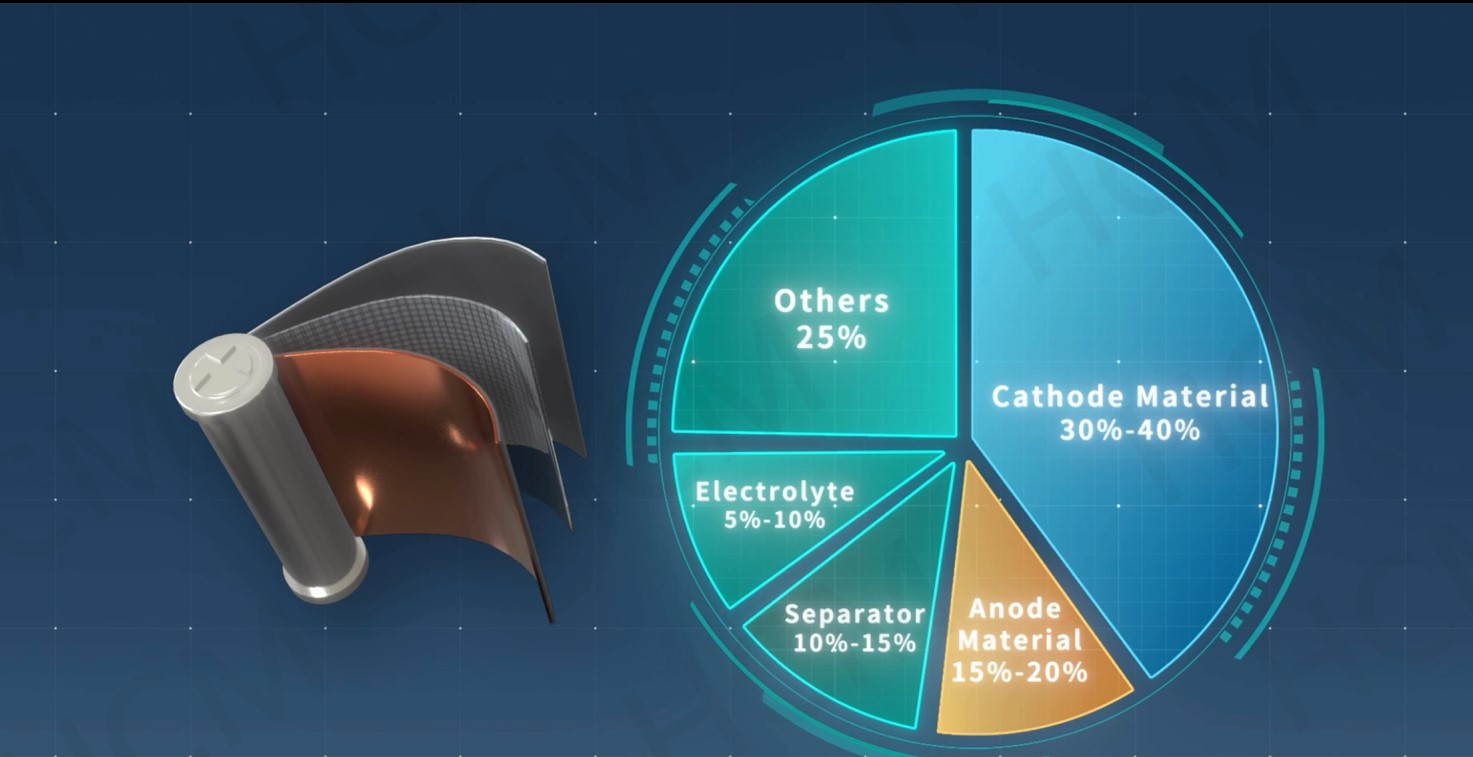

There is truth to that. A battery is built from core components, including the cathode, electrolyte, separator, and anode. Yet the cathode alone accounts for 30–40% of the total battery cost. Choosing the right cathode chemistry is therefore one of the most critical decisions in EV and energy-storage design.

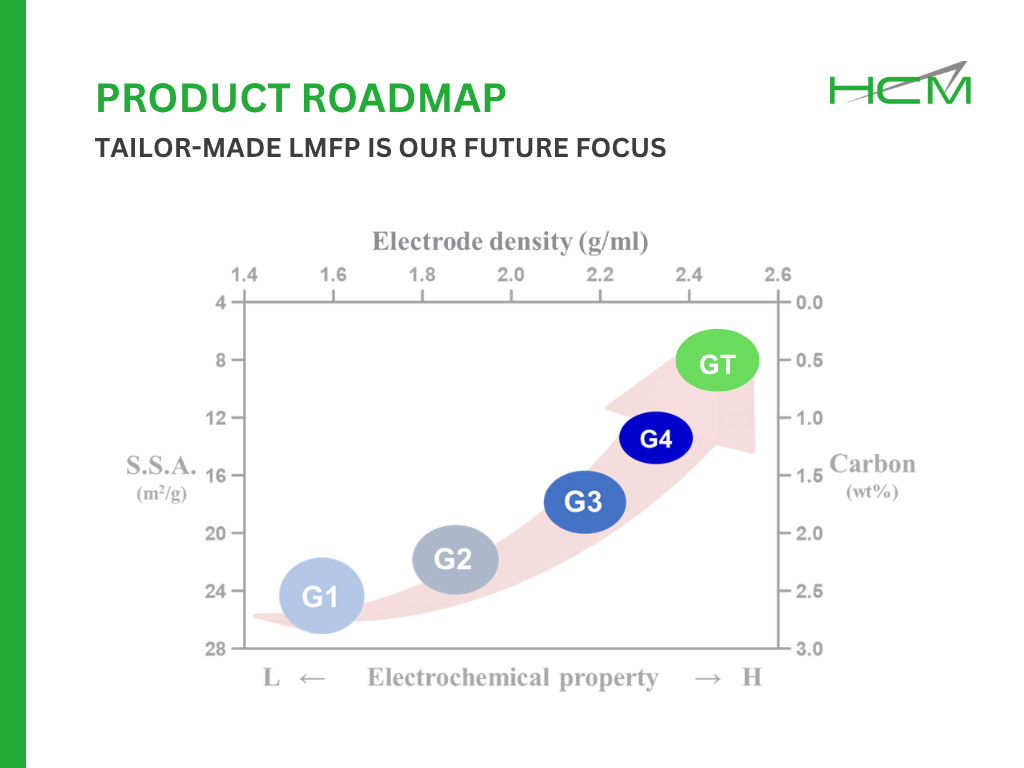

At HCM, we see LMFP as a defining step forward in next-generation battery technology.

Key Advantages of LMFP

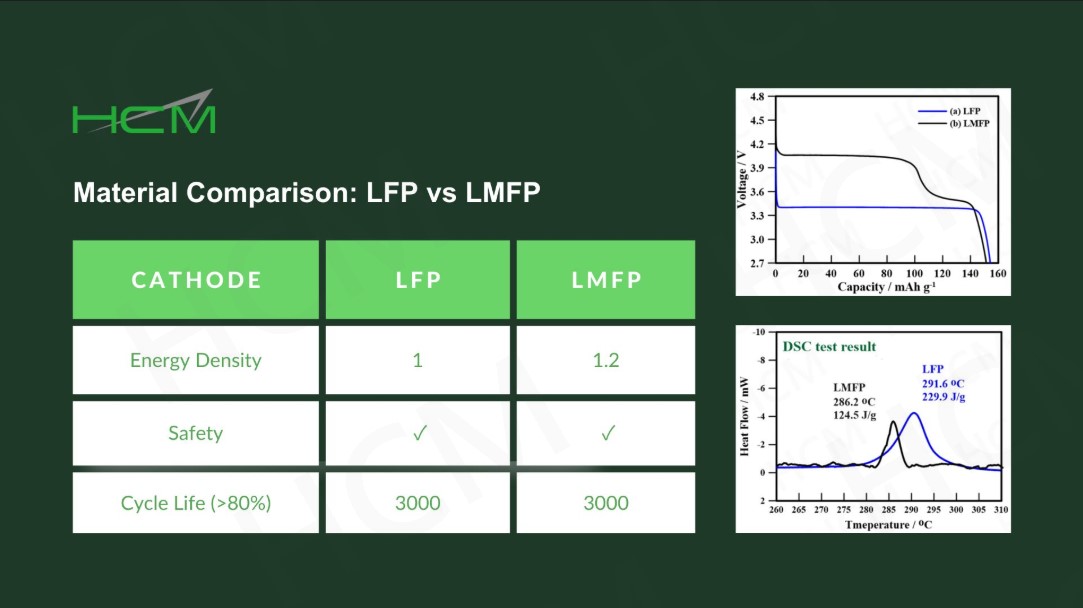

1️⃣ Higher Energy Density

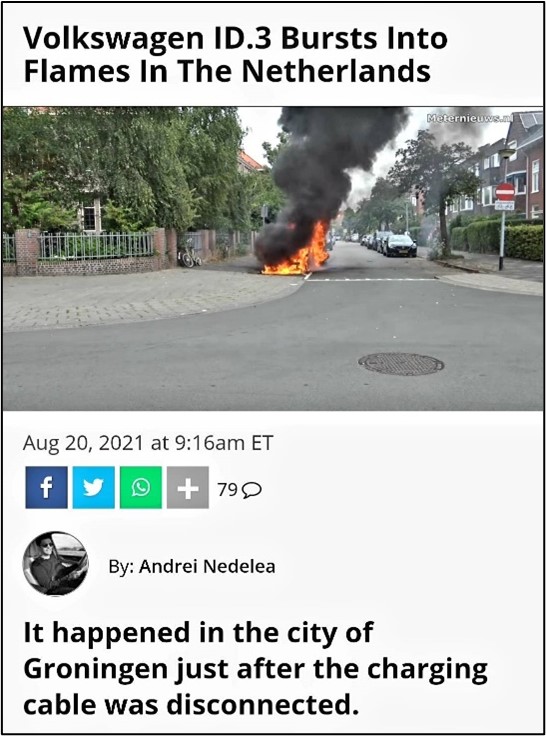

By incorporating manganese, LMFP delivers higher energy density while maintaining excellent thermal safety and a low risk of thermal runaway.

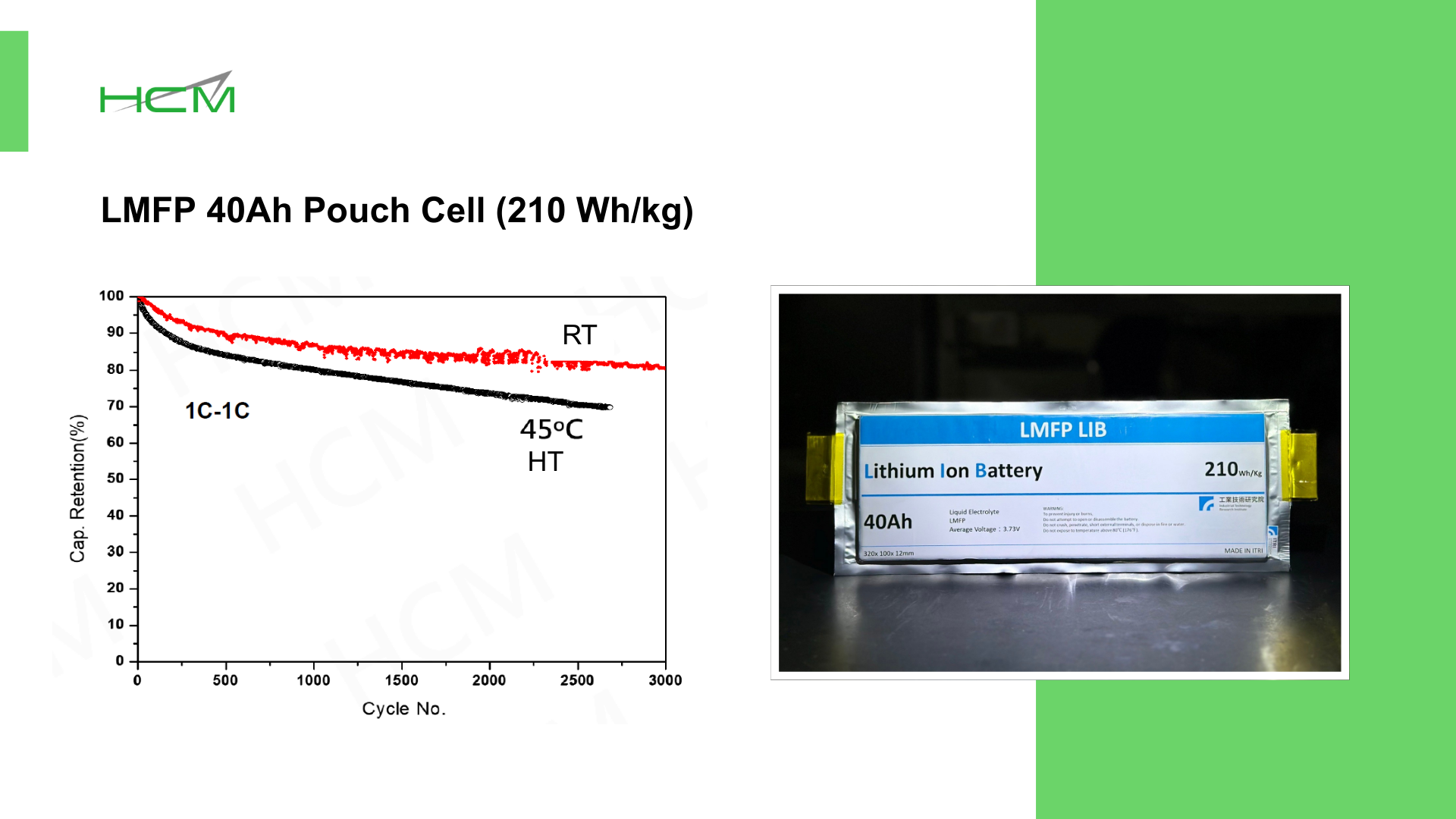

2️⃣ Long Cycle Life

LMFP’s olivine structure provides outstanding cycle performance, supporting longer battery lifespan and lower total cost of ownership.

3️⃣ Cost-Effective

Free from nickel and cobalt, LMFP enables more ethical and sustainable electrification while reducing material costs.

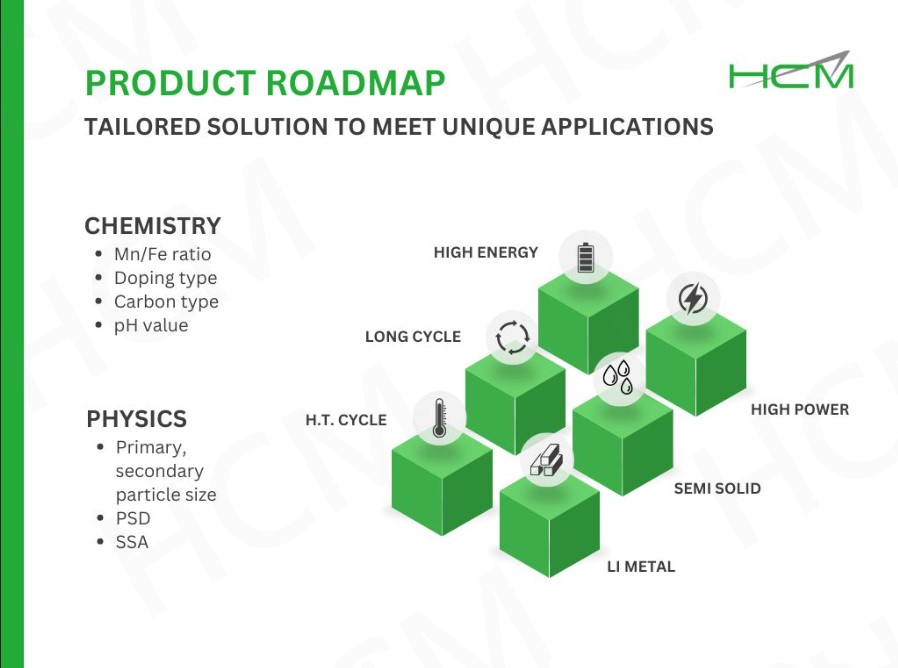

4️⃣ Flexible System Design

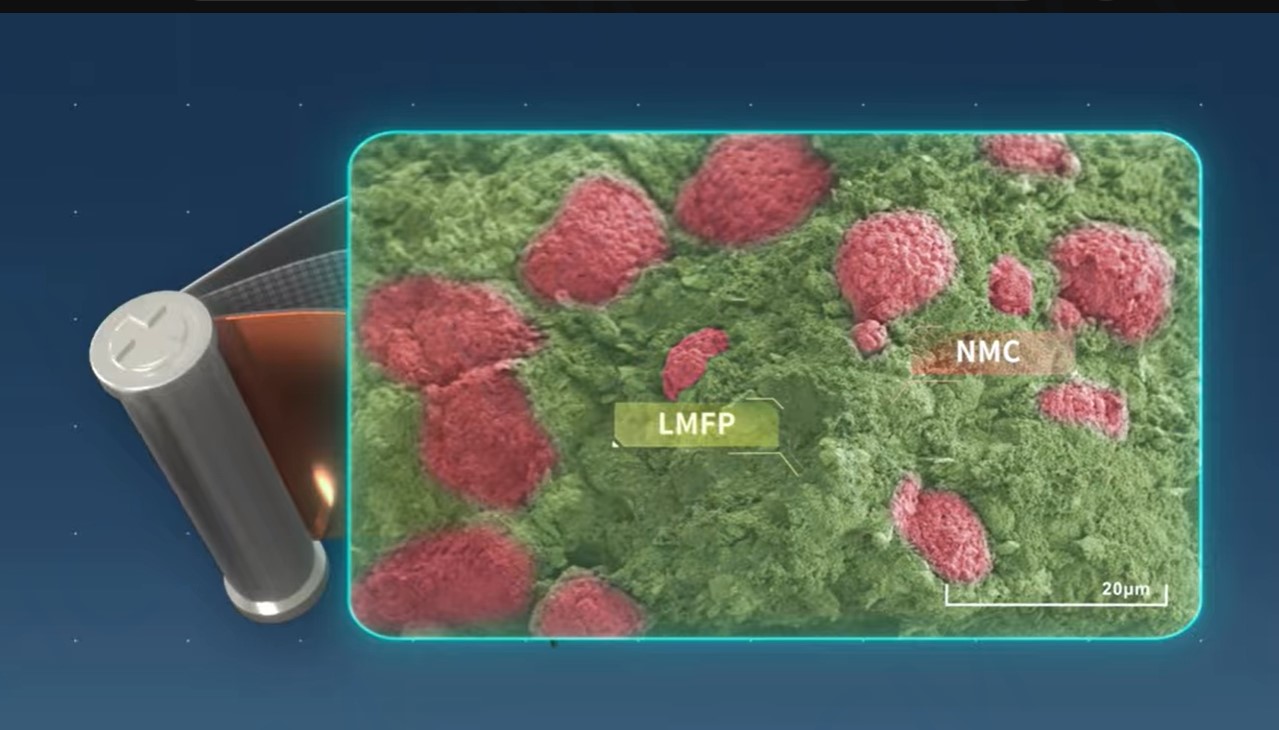

LMFP can be blended with NCM to create tailored cathode systems that balance energy, safety, power, and cost. This flexibility allows OEMs and cell manufacturers to optimize performance for specific applications.

🔗 Connect with us to learn more about our LMFP solutions.

#LMFP #BatteryMaterials #EVBattery #EnergyStorage #CathodeMaterials #BatteryTechnology #SustainableEnergy #EVMobility #CleanEnergy #HCM